“The critical ingredient is getting off your butt and doing something. It is as simple as that. A lot of people have ideas, but few decide to do something about them now. Not tomorrow. Not next week. But today. The true entrepreneur is a doer, not a dreamer." – Nolan Bushnell

Forget the media hype. What we are currently experiencing is not a ‘new normal’ but rather a ‘next normal’. Heraclitus said it first around 2,500 years ago, and it holds true to this day: “The only real constant in life is change”.

Indeed, throughout recent history, life on earth changed dramatically following key events such as world wars, cultural revolutions, natural disasters and, of course, pandemics. Most of us humans feel safe with routine, which makes us feel in control of our lives.

However, there are certain individuals out there who thrive on the unfamiliar, which is one of the key characteristics found in most entrepreneurs. Their resilience and business acumen are sparked when deviating from a workday routine, allowing them to flourish beyond the structure of a major organisation.

Working from home (or smaller premises) and finding a feel-good niche becomes the new USP, and these individuals not only endure but prosper. A home office or studio saves time and money and frees you to invest creative energy into merging your work and passion.

Small entrepreneurs also tread more lightly on the planet. They spend less time burning fossil fuels, minimising their carbon footprint, while power and data consumption is focused outside of peak hours. All in all, this compels us to ‘make more and consume less’, effectively creating a more ecologically conscious society.

The current start-up boom is inextricably linked to small businesses creating their own futures, with ventures blossoming worldwide. According to Forbes Magazine and the US Census Bureau, the United States has ramped up a year-on-year increase of 95% in new start-ups between July 2019 and 2020.

Furthermore, figures from McKinsey indicate a 20% growth in France, 14% in Japan, and a leap of 30% in the UK over similar periods between 2019 and 2020. These surges in entrepreneurial activity are linked to retrenched workers reclaiming their future, often while taking advantage of new opportunities to follow their passion.

Resilience does not mean SMEs are guaranteed to survive – despite the current growth trend – especially here in South Africa. A McKinsey report on SMEs across 12 industry sectors in South Africa has observed various localised challenges.

“Limited access to low and medium-cost funding is a constraining factor, with less than 6% of SMEs receiving government funding, and only 9% sourcing funding from the private sector,” the report states. In addition, payment relief and government loans – including UIF and PAYE – are either not received or accessed, often due to a lack of communication or information.

Add to this South Africa’s high levels of endemic corruption, ongoing load-shedding and water shortages, the collapse of major parastatals and a general lack of good governance, and you cannot help but have a dim view of the future.

Despite this, tens of thousands of entrepreneurs in South Africa have taken the start-up plunge, and they have set their sights on creating successful business enterprises, despite the rot inherent to the system. These are some of their stories.

Wawa Wooden Surfboards

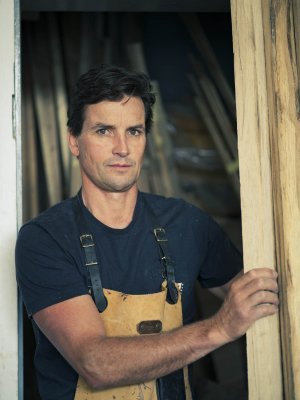

Cobus Joubert (51) started WAWA Wooden Surfboards in 2011 (after shaping his first board way back in 2000). The name originated from the Brazilian name ‘wawa’ for a hardwood species from Africa, used to craft handmade boards in those early days.

“Most of our contemporary boards use lighter woods these days, mostly those environmentally friendly off-cuts we can obtain from timber harvested or sourced locally, including paulownia, Karoo agave, cypress, cedar, cork, walnut and the likes. We also like to remind our tribe that WAWA is short for Wood And Waves, or We Are Water,” says Joubert.

“Our board-building philosophy boils down to ‘what you put in, you get out’. Quality, respect for our roots, and a commitment to the sanctity of nature are all cornerstones of what we do. The manufacturing process embodies the ideals of sustainability through utilising natural materials that are simple, strong and durable,” he explains.

Every WAWA craft comes packaged with this promise: ‘Functional, quality design culminates in a durable product, and our USPs start with lightness and strength’. Light wood combines with super-light recycled EPS to create a composite using wood, foam and bio-resin.

“Add to this function – trusted shapes, shaped by surfers – and custom designs, and you’ve created a dream board for that individual surfer in search of the perfect wave,” he continues, adding, “Boards are the perfect combination of utilitarian design and aesthetic beauty, so we need to consider the buoyancy, manoeuvrability, flex and friction, all while striving to create eye candy of the highest level.”

To the uninitiated, it’s hard to imagine that any natural material can match the lightness of synthetic foam blanks and resin, but Karoo agave (the alien sisal plant) competes with Balsa wood in weight. This is glued into flat sheets from which basic ‘blanks’ are cut before adding an erythrina stringer, agave ribs, and recycled foam and cork to give the board structure and form. “Wood has memory and retains its amazing flex properties, and this is what gives our boards their unique ‘life’ under your feet while carving along a wave,” Joubert smiles.

“Our WAWA philosophy is to use what’s at hand, and this goes back to the resourcefulness of simpler times when broken things were fixed, and available materials were used. So anything goes, from upcycled ceiling board or drywalling for blanks to trying new woods, especially alien species. Making waste into something lasting AND pleasurable…that really makes us feel like we’ve achieved the best possible outcome for everyone concerned!

“Social media has changed the way we do business and has increased our potential reach to the furthest corners of the globe. These days, our sales are probably split down the middle between South African and international buyers. So, made in South Africa for the world, but always with functionality and quality as our priority.”

Backstory Turning

Jacques Maree (40) started Backstory Turning in 2019 just as the pandemic imploded onto the global scene. His focus has been unashamedly environmental right from the start, with each of his handmade pens crafted entirely out of recycled material.

“Our pens are made from plastic lids and caps, discarded bottles, tubes and other synthetic litter collected from our mountains and beaches, as well as those plastics destined for landfill sites. So, the plastic used in our pens has had a previous life, or ‘backstory’, thus the name,” explains Maree.

“The materials used are the result of plastic removed from our beautiful natural environment near Cape Town. As I have little control over the way melted plastic swirls and patterns, no two pens will ever be alike, and this makes them the most unique writing tools in the world.

“I’ve been trail running for years in and around the Mother City and have been amazed at all the plastic rubbish on the mountains,” says Maree, adding that instead of simply collecting and relocating this to landfill sites, he wanted to turn rubbish into something useful and arty.

“Everything except the nibs, clips and refills is 100% handmade. The process of turning the plastic blanks into usable sections for the pens is a craft involving woodturning and other carpentry skills. The choice of colours used for each pen and the sequence in which I melt them to form a blank becomes an art in itself.”

Backstory pens are packaged with a handmade display stand made from discarded Japanese beech wood that was originally church pews, then became floorboards, and end up as custom pen stands. Presently, sales and distribution are focused solely on South Africa, but a brand-new website should soon see the pens ‘make their mark’ internationally.

“The pen components that I use are aluminium, steel or titanium. Along with the plastic bodies that I create, you are guaranteed a pen that will last a lifetime, and this equates to fewer pens ending up in rubbish dumps (and in the ocean)! Each Backstory pen comes packaged in a cardboard gift box with a signed certificate of authenticity and is 100% recyclable.”

www.facebook.com/backstoryturning/

Ballo Sunglasses

Alistair Barnes (37) started Ballo in 2013, way before the pandemic arrived, but his business has been booming over the past couple of years. ‘Ballo’ combines his family name, Barnes, with his mother's maiden name, Gallo. A happy synchronicity is that ‘Ballo’ in Italian also means ‘I dance’ (and Alistair loves to dance).

“Our frames are all handmade in Woodstock from sustainable material using recycled paper, upcycled wood, fabric or advertising billboards, organic hemp and sustainably sourced cork,” Barnes explains, adding that the brand is aimed at buyers in search of unique and non-traditional eyewear.

“We have a strong local following, but most sales used to be to tourists visiting Cape Town or through the export market. The manufacturing process includes 23 stages, all performed by hand or hand-operated tools. I consider art to be something with no functional purpose, so I would describe our sunglasses as ‘hand-crafted’, I suppose,” he continues.

Barnes realised that being sustainable meant keeping the business afloat and their employees at work, and to survive the pandemic, they had to refocus their business model. “We changed our policy on our website from not supplying overseas orders to shipping internationally, and added in planting a tree for every pair we shipped to offset the shipping carbon footprint.

“We work closely with GreenPop as a way to give back to local causes and NGOs. In 2021, we joined 1% For the Planet as a contributing member, which means 1% of turnover is donated to their causes. We’ve also introduced a made-to-order production protocol for online orders in a move towards zero waste,” says Barnes.

Ballo further tweaked their post-pandemic offerings to introduce fabric facemasks, alien timber cutting boards and beeswax candles. All their packaging is recycled cardboard, and they pride themselves on their progressive employment practices, including flexi-time and profit-sharing. “I try to approach all business decisions with an open mind and build employee relationships on compassion and mutual respect, rather than hierarchical fear.”

Stubbs Bespoke

David Michael Stubbs (59) is based in the small seaside village of Scarborough and rates as a true legend of South African surfboard shaping. A few years ago, he stumbled upon a brand new business trajectory while researching a balance bike for his son, then five years old.

“I went online to find some ideas and saw the stunning wooden bicycles being crafted around the world, and was inspired to create my own velo dream machine. This very much started as a hobby and is now a ‘semi-business’ idea, but it has proven to be both a time-consuming and expensive procedure,” Stubbs says.

“I started working on a CNC process, cutting two super-thin front triangles and joining these by infusing carbon fibre to construct a light, strong and stiff frame. The chain and seat stays are laminated and then pressed to create the curves, making for superb vibration absorption.”

Stubbs utilises European white ash (sourced from a sustainable importer) and uses as much of the raw wood as possible to reduce wastage. All finishings and detailing are done by hand, making labour one of the key cost factors.

“I’ve put the bike business on ice until next year to ride out the after-effects of the pandemic,” says Stubbs. At around R40,000 a frame, Bespoke bikes are on par with European prices, but there will always be a market for a ride as beautiful as this.”